Details

Belt dryer scope of application and selection

Selection

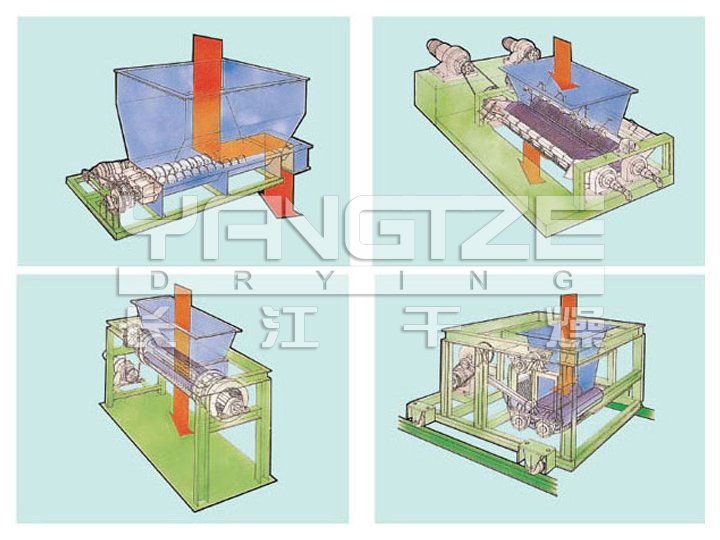

Use of belt dryer is very wide, present in the pharmaceutical, food, biological, chemical and other fields already have it handy. However, in each area of its selection criteria is not the same, because the requirements and parameters of the dried material in various fields have a greater difference. For example: in the pharmaceutical industry (especially medicine), extract viscosity are generally large, and drying temperature requirements more stringent, the melting point of control to be precise (especially polysaccharide material), the control range to meet the different degree of vacuum heating and temperature requirements of section to have online auto tuning function, and so on. Also to try to improve the detection system to comply with pharmaceutical GMP standards. For the food industry, the material extract solids content is generally greater (65%), production requirements and product specific volume and appearance of a vacuum belt dryer of the key selection criteria, food-grade vacuum belt dryer selection process has two elements must not be ignored: one unit of energy consumption than the problem, the other is pre-transport equipment such as raw material, dried and finely pulverized product packaging. As for biological, chemical use on vacuum belt dryer due to the different forms of the product, and therefore the selection criteria is extremely complex, so the need to exercise caution.

The third step is to select a vacuum belt dryer is to investigate the actual processing capacity and production scale manufacturers. At present the country with a series of design and production capacity of the enterprise up to no more than three, in particular, the annual output of up to 10 vacuum belt dryer or more (especially more than 6 layers dried bed of large or very large equipment) manufacturers estimate only 1 to 2. Therefore, most of the domestic manufacturers are difficult to form part of the standardization process vacuum belt dryer, which is to provide customers with products as well as maintenance and repair parts and accessories are interchangeable there is a big problem, often directly affect the user productivity, in addition to the lack of practical experience, the mechanical structure of the device, the configuration is reasonable, precision manufacturing, and so can not be considered very comprehensive. The vacuum belt dryer due to the large volume, auxiliary equipment and more high configuration requirements, the middle part of the complex, etc., to keep the equipment running for a long time to stabilize and easy.The price of this device is also more expensive, users are generally optimistic about its drying capacity and technical advantages of the use of huge amounts of money while purchasing, so are hoping to recover the cost as soon as possible to improve the economic efficiency of enterprises. Therefore, in the procurement of equipment be sure to choose the size, design and manufacture of practical experience and reliable service with the manufacturer to ensure that the system can be assured, of course, this provided by the manufacturer of vacuum belt dryer is generally slightly higher price point, but for users, the use of a sense of security, customers must not covet a moment because of low price and may affect the overall situation.

For better ventilation sheet, strip, dry granular materials, for dehydrated vegetables, Chinese Herbal Medicine and other high moisture content, and the material does not allow high temperature materials are particularly suitable; the series dryer has a fast drying, high evaporation strength, product quality and good benefits. For dehydrated cake paste materials, to be made after granulation or rod can also be dried.

- 2016-08-06 > Belt dryer common faults and maintenance during use

- 2016-08-06 > Eight kinds of drying equipment used in chemical and pharmaceutical industry

- 2016-08-06 > Spray drying desulfurization technology in the protection of ecological environment

- 2016-08-06 > Chinese medicine extract special spray dryer and high-speed extraction rate comparison

- 2016-08-06 > Belt dryer scope of application and selection

- 2016-08-06 > Efficient mixing granulator of calcium carbonate industry development status and characteristics

- 2016-08-06 > Safe use of hot air circulation oven and four points to note

- 2016-08-06 > Rice Dryer market will be a new trend