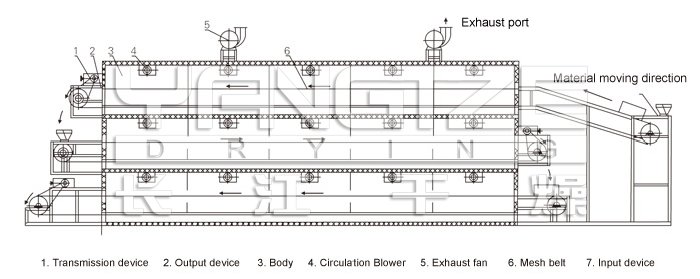

DW Multi-belt Dryer

PRODUCT INTRODUCTION

The belt drier is continuous drying equipment in batch. It is suitable for drying the raw materials that is in the shape of piece, s trip or granule and is good in permeability. Particularly it is suitable for such raw materials that contain high moisture and are not permitted high temperature for example, dehydrated vegetable,catalyst, drinking tablet of Chinese traditional medicine. Its features are fast in drying speed, strong in vaporization, good in quality of products. Typical products Dehydrated vegetable, granule feed, monosodium glutamate, check extraction, organic pigment, synthetic rubber, propylene fiber, medicine, medical material, small wooden products, plastic products, aging or solidifying for electronic elements. For pasted raw material such as filter cake, it can be dried after shaped through granulator or extruder.

DESCRIPTIONS

DWB series many layers belt dryer is used in the material hard to dry and low dry speed. The equipment s tructure is compact. It covers small area with easy operation, convenient maintain and steady running. The equipment extend and promote the heat wind circle oven which design the dryness process with different heat wind circle as per the dryness characteristics of materials. It is widely used in chemical, metallurgy industry, food, packaging. The dryer has lots of superiorities as high efficiency, saving energy, easy management, larger output, constant product and varied ability .

PRODUCTION FLOWCHART

TECHNICAL PARAMETERS

| Item \ Model | DW3-1.2-8 | DW3-1.2-10 | DW3-1.6-8 | DW3-1.6-10 | DW3-2-8 | DW3-2-8 |

| quantity of unit | 4×3 | 5×3 | 4×3 | 5×3 | 4×3 | 5×3 |

| width of belt(m) | 1.2 | 1.6 | 2 | |||

| length of dry section(m) | 8×3 | 10×3 | 8×3 | 10×3 | 8×3 | 10×3 |

| thickness of raw material spreading(mm) | 10-80 | |||||

| operation temperature(oC) | 50-140 | |||||

| steam pressure(MPa) | 0.2-0.8 | |||||

| steam consumption (kg/h) | 360-600 | 420-720 | 450-840 | 480-960 | 480-960 | 630-1350 |

| area of heat exchange(m2) | 816 | 1020 | 1056 | 1320 | 1344 | 1680 |

| dry capacity kg water/h | 150-450 | 220-550 | 240-600 | 280-750 | 280-750 | 350-900 |

| quantity of fan | 14 | 17 | 14 | 17 | 14 | 17 |

| total equipped power inside(kw) | 30.8 | 37.4 | 42 | 51 | 56 | 68 |

| total equipped power (kw) | 35.3 | 41.9 | 46.5 | 55.5 | 60.5 | 72.5 |

| overall dimensions(L×W×H) | 9.77×2.2×4.5 | 11.77×2.2×4.5 | 9.77×2.6×4.7 | 11.77×2.6×4.7 | 9.77×3.06×4.9 | 11.77×3.06×4.9 |

| weight kg | 4800×3 | 5780×3 | 5400×3 | 6550×3 | 6350×3 | 7800×3 |

Note: The vaporized moisture shown in Fig. will be decided in accordance with the drying temperature of material, thickness of spread material and stay time.

- 2016-08-06 > Belt dryer common faults and maintenance during use

- 2016-08-06 > Belt dryer scope of application and selection

- 2016-08-06 > Eight kinds of drying equipment used in chemical and pharmaceutical industry

- 2016-08-06 > Spray drying desulfurization technology in the protection of ecological environment

- 2016-08-06 > Chinese medicine extract special spray dryer and high-speed extraction rate comparison

- 2016-08-06 > Efficient mixing granulator of calcium carbonate industry development status and characteristics

- 2016-08-06 > Safe use of hot air circulation oven and four points to note

- 2016-08-06 > Rice Dryer market will be a new trend