Vacuum Belt Dryer

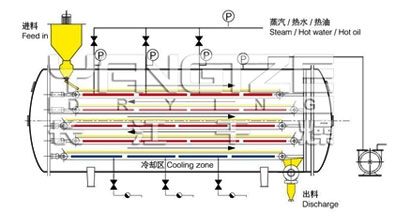

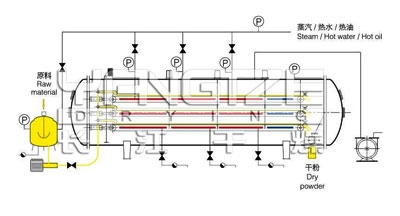

Low-temperature vacuum liquid multilayer belt dryer is a continuous feeding and discharging vacuum drying equipment. The raw material to be dried is feeded into drying machine through feeding pump, and is well distributed on convey belt through distributing device. The boiling temperature of materials is reduced through high vacuum, and the moisture of liquid raw material is sublimated to gas directly. The convey belt runs on the heating plate at a constant speed, and the internal heat source of heating plate can be steam, hot water or electrical heating, With the running of convey belt, the temperature is adjustable up and down according to the specific characteristics of material from evaporating and drying in the front to cooling discharging in the end. The discharging end is equipped with a specific vacuum grinding device to grind products into different granularity. The dried powder can be automatically packaged or used by the following process.

|

The whole set of process is in automation, channelization and continuity.

The targets of continuous feeding and discharging in vacuum condition have been reached.

The operations of drying, smashing and pelletizing can be completed in vacuum condition.

The operation cost is 1/3 of vacuum drying oven and spray drying, and 1/6 of freeze drying.

The maximum operators are only two, the human costs are reduced greatly.

Drying temperature can be adjusted from 25℃ to 150℃ according to process technological requirements.

Heat sensitive materials will not be denaturated or contaminated.

Drying powder can be discharged in 30-60min and the discharging rate is 99%.

Can dry liquid and pasty materials with high viscosity difficult drying.

Online automatic-cleaning, in accordance with GMP standard

|

Model |

Diameter |

Length |

Height |

Heating area |

Heating temperature |

Moisture content of feeding raw material |

Moisture content of dried product

% |

Heating resource

|

Water evaporation capacity

kg/h |

Main dryer power

kw |

|

ZD4-2

|

1000

|

5060

|

2100

|

4

|

20-120

|

20-80

|

0.2-5

|

Steam or Hot oil

|

3-4 |

4.00 |

|

ZD20-4

|

1400

|

8850

|

2650

|

20

|

15-18 |

8.00 |

||||

|

ZD30-4

|

1700

|

9800

|

2700

|

30

|

20-28 |

10.00 |

||||

|

ZD60-6

|

2200

|

10800

|

3550

|

60

|

45-55 |

14.00 |

||||

|

ZD80-5

|

2200

|

16100

|

3550

|

80

|

65-75 |

14.50 |

||||

|

ZD100-6

|

2200

|

16100

|

3550

|

100

|

80-90 |

15.50 |

||||

|

ZD120-7

|

2200

|

16100

|

3550

|

120

|

100-110 |

16.50 |

||||

|

ZD160-8

|

2800

|

17300

|

4100

|

160

|

120-140 |

18.50 |

||||

|

ZD186-10

|

2800

|

17300

|

4150

|

186

|

150-170 |

25.50 |

||||

|

ZD200-10

|

2800

|

17300

|

4150

|

200

|

160-180 |

25.50 |

-

The low-temperature continuous vacuum multilayer belt dryer

-

The low-temperature continuous vacuum multilayer belt dryer

-

The low-temperature continuous vacuum multilayer belt dryer

-

The low-temperature continuous vacuum multilayer belt dryer

-

The low-temperature continuous vacuum multilayer belt dryer

-

The low-temperature continuous vacuum multilayer belt dryer

- 2016-08-06 > Eight kinds of drying equipment used in chemical and pharmaceutical industry

- 2016-08-06 > Spray drying desulfurization technology in the protection of ecological environment

- 2016-08-06 > Chinese medicine extract special spray dryer and high-speed extraction rate comparison

- 2016-08-06 > Belt dryer common faults and maintenance during use

- 2016-08-06 > Belt dryer scope of application and selection

- 2016-08-06 > Efficient mixing granulator of calcium carbonate industry development status and characteristics

- 2016-08-06 > Safe use of hot air circulation oven and four points to note

- 2016-08-06 > Rice Dryer market will be a new trend