CG Forming Machine

PRODUCT INTRODUCTION

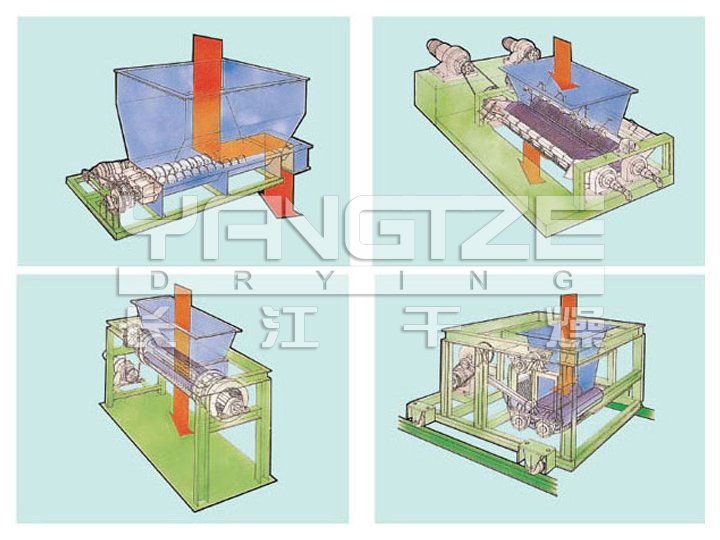

◎Slot forming machine: consists of hopper and roller with 2 s lots in order to increase the surface area of material for granulation. The raw material will be sucked by rotating roller towards inside and then formed granule cut by outside scrapers that rotate counterclock wise direction consists of hopper, roller with 2 slots and U type vibrating sieve in order to increase the surface area of material for granulation. The raw material will be contacted with vibrating sieve and pressed through rotating sieve and then form column granule.

◎ Level stetching forming machine: consists of hopper and vibrating sieve with 2 rollers in order to increase the surface area of material for granulation.

◎Roller style granulator: The raw material will be contacted with vibrating sieve and pressed into the sieve through left and right motion of roller and the formed round granule.

- 2016-08-06 > Eight kinds of drying equipment used in chemical and pharmaceutical industry

- 2016-08-06 > Spray drying desulfurization technology in the protection of ecological environment

- 2016-08-06 > Chinese medicine extract special spray dryer and high-speed extraction rate comparison

- 2016-08-06 > Belt dryer common faults and maintenance during use

- 2016-08-06 > Belt dryer scope of application and selection

- 2016-08-06 > Efficient mixing granulator of calcium carbonate industry development status and characteristics

- 2016-08-06 > Safe use of hot air circulation oven and four points to note

- 2016-08-06 > Rice Dryer market will be a new trend