Details

Efficient mixing granulator of calcium carbonate industry development status and characteristics

Sources: | Release date:

2016-08-06

| Pageviews:

Article Keywords:

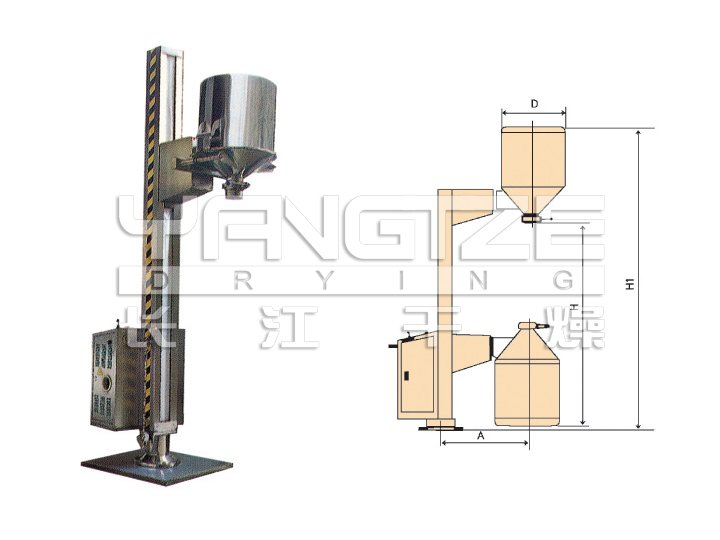

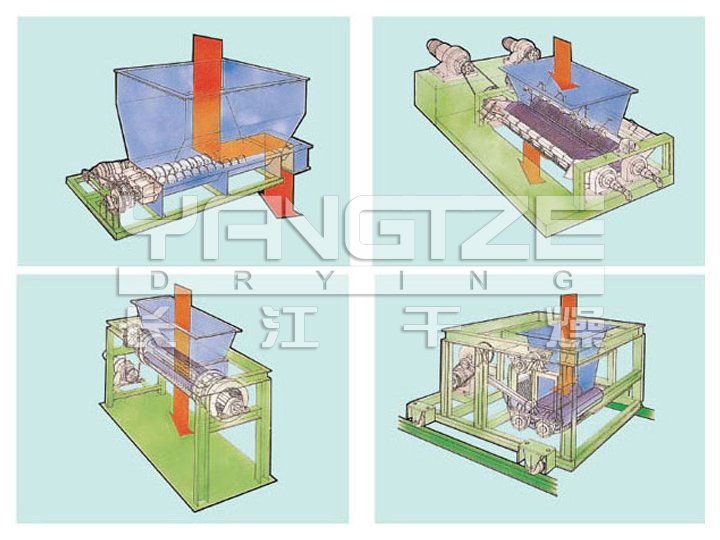

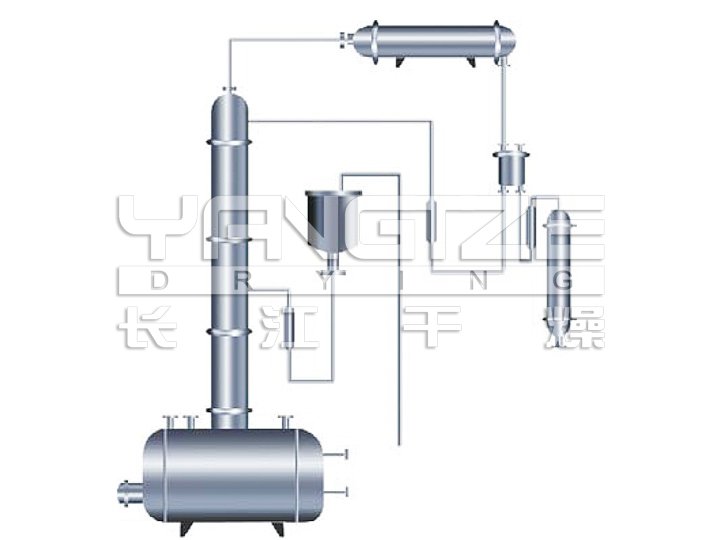

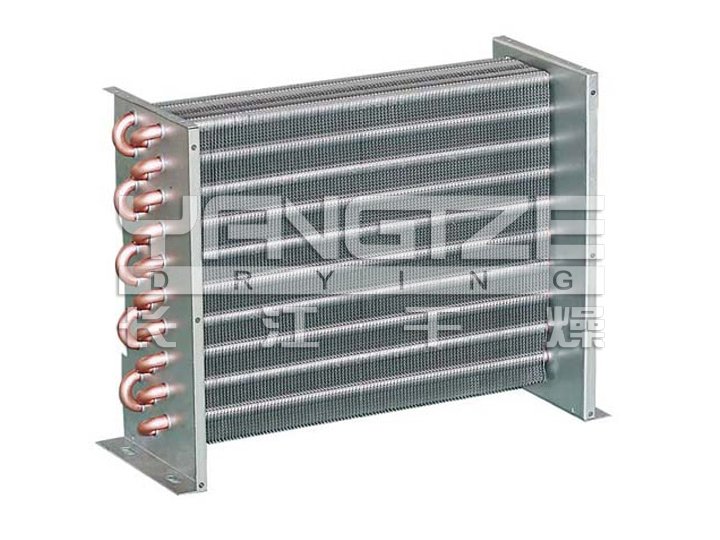

Granulating machine with the general requirements of the calcium carbonate industry is a high thermal efficiency, low energy consumption, simple configuration, easy to control, small footprint, operating environment health and safety. At present, the salt industry to use more common and efficient mixing granulator are: rotary tube dryer, indirectly heated rotary driers, disc continuous dryer, air dryer (divided pulse stream, flow rotation, positive and negative two stage air drying), spin flash dryer, rotary drum dryer, spray dryer (divided granulated, powdered, centrifugal, pressure), vibration fluidized bed dryer, the static vacuum dryer, hot air circulation oven , rake, paddle vacuum dryer, boiling dryer (horizontal, vertical) and the like.

These highly efficient mixing granulator for product quality to provide a guarantee, however, there are exhaust collect "dust" problem. Due to the increasing nanoscale products, more and more original fine particle size, water content of paste materials potentially improve, companies continue to add to the large scale development, enterprise combination eager efficient mixing granulator. In particular, some large-tonnage products, such as precipitated calcium carbonate, the current national production of 300 million tons, the smallest production line with an annual output of 10,000 tons, 100,000 tons of scale to five sets of efficient mixing granulator, a business plan to get 50 in Guangxi tons, according to the current level of efficient mixing granulator, regardless of area or product after the dry exhaust equipment revenue "dust" is a great amount.

According to the current industry commonly used pulse bag filter, the operating environment is very bad, we must take effective measures to solve them. We therefore hope that the device research and development unit focused on solving two problems, one object of fine high water content of paste and dried issue, and second, after the object dry exhaust collect "dust" industrial hygiene problems. Still calcium carbonate industry, for example, more than 200 companies in the efficient mixing granulator selection, basic use of indirectly heated rotary driers, disc continuous dryer, rotary tube dryer or the like, although the production efficiency are met energy consumption and exhaust collect "dust" is not ideal, a calcium carbonate into the business, from the ground to the roof are covered with a layer of white calcium carbonate powder, even in the office furniture is a layer of white, in this regard there are management issues, more importantly, after the dry exhaust collect "dust", but off. The industry has recently introduced a US company DuPont dust removal equipment, basically solved the problem.

Thus, the combination should be efficient mixing granulator comprising: providing a heat source equipment, one, two efficient mixing granulators, exhaust collect "dust" and other equipment, you want the device manufacturing, research units, high thermal efficiency, low energy consumption, simple configuration, easy to control aspects of an issue, make a fuss in terms of a combination of efficient mixing granulator, serve others, develop their own. If the drying problem of calcium carbonate industry solved, realized device efficient, environmentally friendly, like other varieties of dried problem solved.

These highly efficient mixing granulator for product quality to provide a guarantee, however, there are exhaust collect "dust" problem. Due to the increasing nanoscale products, more and more original fine particle size, water content of paste materials potentially improve, companies continue to add to the large scale development, enterprise combination eager efficient mixing granulator. In particular, some large-tonnage products, such as precipitated calcium carbonate, the current national production of 300 million tons, the smallest production line with an annual output of 10,000 tons, 100,000 tons of scale to five sets of efficient mixing granulator, a business plan to get 50 in Guangxi tons, according to the current level of efficient mixing granulator, regardless of area or product after the dry exhaust equipment revenue "dust" is a great amount.

According to the current industry commonly used pulse bag filter, the operating environment is very bad, we must take effective measures to solve them. We therefore hope that the device research and development unit focused on solving two problems, one object of fine high water content of paste and dried issue, and second, after the object dry exhaust collect "dust" industrial hygiene problems. Still calcium carbonate industry, for example, more than 200 companies in the efficient mixing granulator selection, basic use of indirectly heated rotary driers, disc continuous dryer, rotary tube dryer or the like, although the production efficiency are met energy consumption and exhaust collect "dust" is not ideal, a calcium carbonate into the business, from the ground to the roof are covered with a layer of white calcium carbonate powder, even in the office furniture is a layer of white, in this regard there are management issues, more importantly, after the dry exhaust collect "dust", but off. The industry has recently introduced a US company DuPont dust removal equipment, basically solved the problem.

Thus, the combination should be efficient mixing granulator comprising: providing a heat source equipment, one, two efficient mixing granulators, exhaust collect "dust" and other equipment, you want the device manufacturing, research units, high thermal efficiency, low energy consumption, simple configuration, easy to control aspects of an issue, make a fuss in terms of a combination of efficient mixing granulator, serve others, develop their own. If the drying problem of calcium carbonate industry solved, realized device efficient, environmentally friendly, like other varieties of dried problem solved.

Previous:None

Related articles

- 2016-08-06 > Eight kinds of drying equipment used in chemical and pharmaceutical industry

- 2016-08-06 > Spray drying desulfurization technology in the protection of ecological environment

- 2016-08-06 > Chinese medicine extract special spray dryer and high-speed extraction rate comparison

- 2016-08-06 > Belt dryer common faults and maintenance during use

- 2016-08-06 > Belt dryer scope of application and selection

- 2016-08-06 > Efficient mixing granulator of calcium carbonate industry development status and characteristics

- 2016-08-06 > Safe use of hot air circulation oven and four points to note

- 2016-08-06 > Rice Dryer market will be a new trend

Related products