GFG High-Efficiency Fluidizing Dryer (Fluid Bed)

WORKING PRINCIPLE

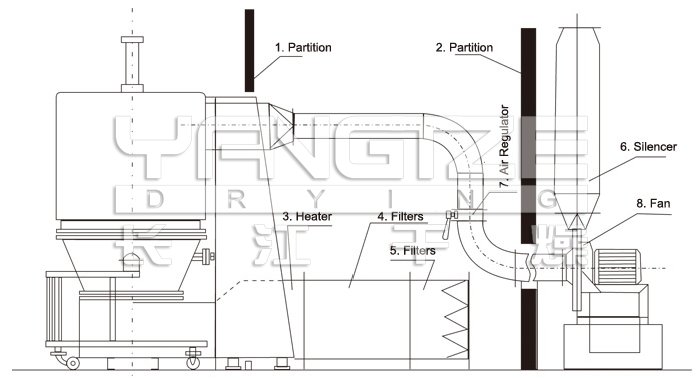

The purified and heated air is introduced from the bottom by the draft fan and passed through the screen plate. The fluidization is formed through stirring and negative pressure in the working room. The moisture will be rapidly evaporated and exhausted so the material can be dried very fast.

FEATURES

1) The structure of fluidization bed is round so it is smooth inside without cleaning dead corners.

2) There is a stirring device inside of the hopper which can avoid agglomeration of wet material.

3) The granule is discharged by tipping over the hopper. The discharged system can be designed as per customer requirements.

4) The dryer is operated at the negative pressure and seal conditions. The air is filtered before enters to the dryer. Therefore, it is simple in operation and convenient in cleaning.

5) The drying speed is fast and the temperature is uniform. The drying time is normally 20~30 min utes for each batch.

APPLICATION

This dryer is widely used for the following materials:

1) Damp granules and powder materials in pharmaceutical, foodstuff, feed, chemi cal, and agrochemical industries.

2) Granules made by extruder, oscillating granulator, and high speed mixing granulator.

3) Special large granule and small blocks that having adhesive property.

4) The material that changes volume during drying process; such as konjak.

PRODUCTION PARAMETERS

TECHNICAL PARAMETERS

| Item | Model | ||||||

| Feeding Capacity (kg) | 60 | 100 | 120 | 150 | 200 | 300 | 500 |

| Fan Power (kw) | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 45 |

| Stirring Power (kw) | 0.55 | 1.1 | 1.1 | 1.1 | 1.1 | 1.5 | 2.2 |

| Stirring Speed (rpm) | 8~11 | ||||||

| Steam Consumption (kg/h) | 141 | 170 | 170 | 240 | 282 | 366 | 451 |

| Working Time (min) | 15-30(It depends on the nature of materials) | ||||||

| Dryer Heigh (mm) | 2700 | 2900 | 2900 | 2900 | 2900 | 3300 | 3500 |

- 2016-08-06 > Eight kinds of drying equipment used in chemical and pharmaceutical industry

- 2016-08-06 > Spray drying desulfurization technology in the protection of ecological environment

- 2016-08-06 > Chinese medicine extract special spray dryer and high-speed extraction rate comparison

- 2016-08-06 > Belt dryer common faults and maintenance during use

- 2016-08-06 > Belt dryer scope of application and selection

- 2016-08-06 > Efficient mixing granulator of calcium carbonate industry development status and characteristics

- 2016-08-06 > Safe use of hot air circulation oven and four points to note

- 2016-08-06 > Rice Dryer market will be a new trend